In the pharmaceutical industry, maintaining product quality is critical to ensuring patient safety and efficacy. A Quality Management System (QMS) is fundamental to achieving these objectives, but as regulatory requirements evolve, the need for a Risk-Based Approach (RBA) becomes essential and this approach helps identify, assess, and mitigate risks to ensure product quality and patient safety while optimizing resources and processes.

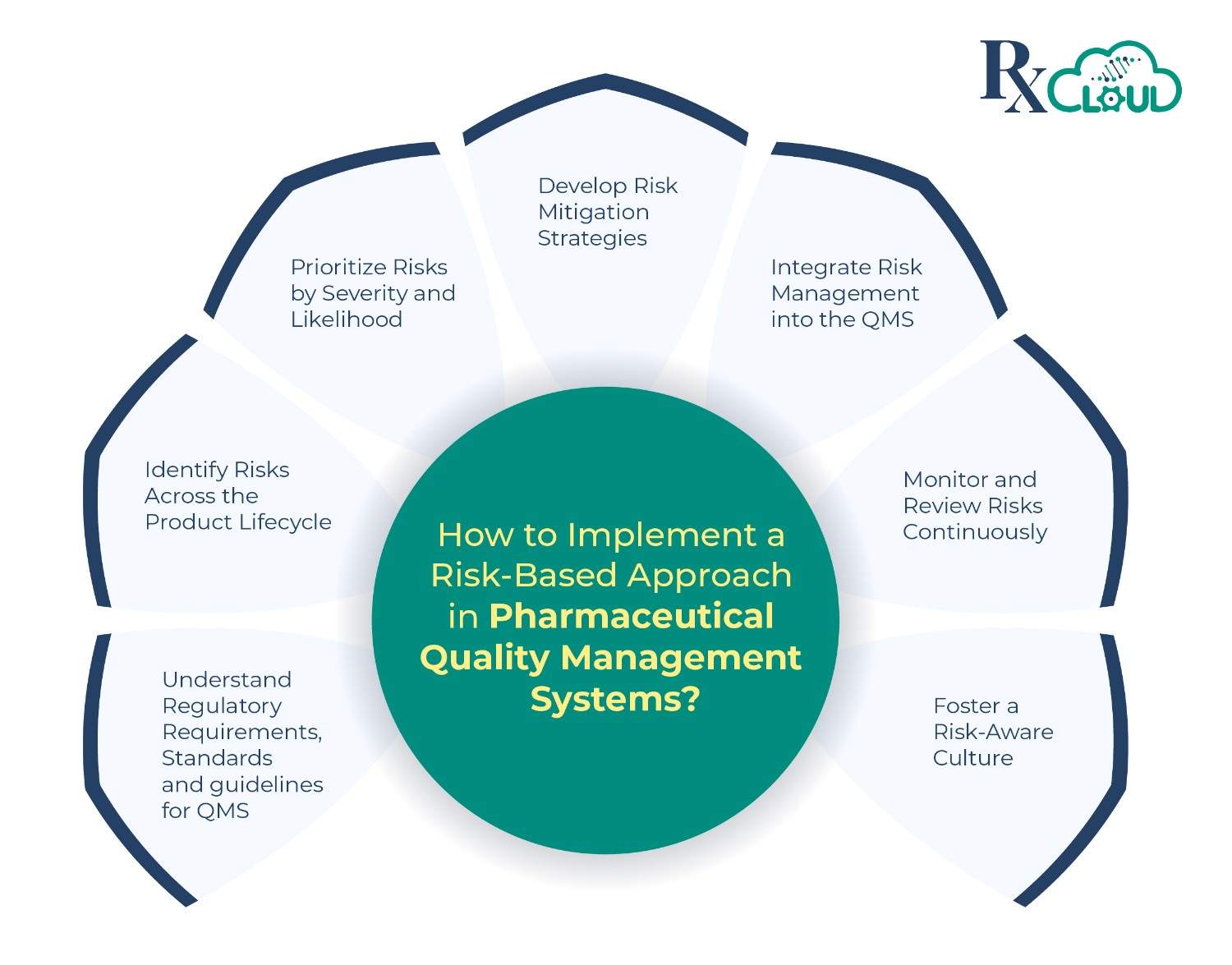

At RxCloud, we implement RBA in pharmaceutical QMS using a 7-step methodology. Here’s how we do it:

1. Understand Regulatory Requirements, Standards, and guidelines for QMS

A successful RBA begins with a thorough understanding of regulatory requirements, guidelines and standards. Regulatory bodies like the FDA and EMA emphasize the integration of risk management into QMS, as outlined in:

ISO 9001:2015: This international standard specifies requirements for a quality management system (QMS) and emphasizes a risk-based approach. It requires organizations to identify risks and opportunities that could impact the QMS’s ability to achieve intended results.

ISO 13485:2016: For medical devices, this standard focuses on quality management systems specific to the medical device industry, incorporating risk management throughout the product lifecycle.

FDA 21 CFR Part 820: In the U.S., this regulation applies to medical devices and includes requirements for a QMS that incorporates risk management principles.

ICH Q9: Provides a framework for quality risk management, offering principles and examples of tools for assessing and managing risks.

ICH Q10: Expands on ICH Q9 by describing a comprehensive Pharmaceutical Quality System (PQS) that includes risk management as a key component.

ISO 14971: Focuses on risk management for medical devices and pharmaceuticals, complementing the ICH guidelines.

EU MDR (Medical Device Regulation (2017/745)) and IVDR (In-vitro Diagnostic Regulation): For medical devices in Europe, these regulations mandate risk management throughout the lifecycle of the device.

ISO/IEC 17025: This standard applies to testing and calibration laboratories and incorporates risk management into the quality management system for these entities

Key Steps:

Review Guidelines: Familiarize your team with SO 9001:2015, ISO 13485:2016, FDA 21 CFR Part 820, ICH Q9, ICH Q10, ISO 14971, EU MDR (2017/745), IVDR, and ISO/IEC 17025 to ensure full regulatory compliance.

Align with Standards: Ensure your QMS risk management processes align with these international standards, providing a robust foundation for RBA.

2. Identify Risks Across the Product Lifecycle

Risk identification is the cornerstone of a successful RBA. This process should encompass every stage of the product lifecycle, from development to post-market surveillance.

Key Steps:

Conduct Risk Assessments: Engage cross-functional teams to identify potential risks in areas such as manufacturing, supply chain, and post-market activities.

Utilize Risk Identification Tools: Use tools like Failure Mode and Effects Analysis (FMEA), Hazard Analysis and Critical Control Points (HACCP), and Fault Tree Analysis (FTA) to systematically identify risks.

3. Prioritize Risks by Severity and Likelihood

Not all risks pose the same level of threat. After identifying risks, prioritize them based on their potential impact on product quality and patient safety, considering both severity and likelihood.

Key Steps:

Classify Risks: Categorize risks into high, medium, or low based on severity and likelihood of occurrence.

Develop a Risk Matrix: Create a risk matrix to visually rank risks, aiding in the prioritization of mitigation strategies.

4. Develop Risk Mitigation Strategies

Once risks are prioritized, focus on developing tailored mitigation strategies. These strategies should be proportionate to the level of risk and might include preventive actions, process improvements, or additional controls.

Key Steps:

Implement Preventive Actions: For high-priority risks, introduce preventive measures to minimize the likelihood of occurrence.

Enhance Controls: Strengthen existing controls or introduce new ones for medium and low-priority risks.

Document Mitigation Plans: Ensure all risk mitigation strategies are well-documented within your QMS, enabling traceability and continuous improvement.

5. Integrate Risk Management into the QMS

Risk management should be fully integrated into all aspects of your QMS, ensuring it influences key processes such as change control, deviation management, and supplier quality management.

Key Steps:

Update QMS Procedures: Embed risk management principles into all relevant QMS procedures to ensure consistent application.

Train Employees: Provide comprehensive training to ensure that all staff understand how to apply RBA in their daily activities.

Implement Continuous Monitoring: Regularly monitor the effectiveness of risk controls and update them as necessary, ensuring your QMS remains dynamic and responsive.

6. Monitor and Review Risks Continuously

Risk management is not a one-time activity; it requires continuous monitoring and periodic review to ensure that controls remain effective and relevant.

Key Steps:

Conduct Regular Reviews: Schedule regular reviews of risk management activities to assess their effectiveness and identify areas for improvement.

Leverage Audits and Inspections: Use internal audits and regulatory inspections as opportunities to reassess and refine your risk management strategies.

Adjust Mitigation Strategies: Be prepared to adjust strategies as new risks emerge or existing risks evolve, ensuring your QMS remains proactive. We also leverage tools to streamline the risk management process.

7. Foster a Risk-Aware Culture

A robust RBA requires a risk-aware culture where everyone understands the importance of risk management and their role in maintaining product quality and safety.

Key Steps:

Promote Awareness: Regularly communicate the significance of risk management to all employees, ensuring it is a shared responsibility.

Encourage Reporting: Create an environment where employees feel empowered to report potential risks or quality issues without fear of retribution.

Reward Proactive Behavior: Recognize and reward employees who actively contribute to improving risk management and quality within the QMS.

Conclusion

Implementing a Risk-Based Approach (RBA) in your Quality Management System (QMS) is essential for maintaining compliance, ensuring product quality, and protecting patient safety. At RxCloud, we specialize in developing and implementing comprehensive QMS frameworks that seamlessly integrate RBA.

By following these 7 steps, you can ensure your QMS not only meets regulatory requirements but also fosters a culture of continuous improvement. This proactive approach enhances both quality and operational efficiency, ultimately protecting patient lives.

FAQs

1. What is the role of a QMS in pharmaceutical risk management?

A QMS provides the framework for identifying, assessing, and mitigating risks that can impact product quality and patient safety, as outlined in ICH Q9 and ICH Q10.

2. Why is continuous monitoring important in a QMS?

Continuous monitoring ensures that risk controls remain effective over time, allowing for prompt identification and management of emerging risks.

3. How often should risk assessments be conducted?

Risk assessments should be conducted regularly, particularly at critical points in the product lifecycle, during significant process changes, or as part of routine QMS reviews.

4. How does a QMS ensure compliance with regulatory guidelines?

A QMS integrates risk management practices in line with ICH Q9, ICH Q10, and ISO 14971, ensuring ongoing compliance with global regulatory standards.

5. What tools are commonly used in QMS for risk identification?

Tools such as FMEA, HACCP, FTA, and risk matrices are commonly used to systematically identify and assess risks in a QMS.